Introduction

What is a die cutting machine, you ask? Die cutting machines are precision tools used to create intricate designs and shapes in various materials, including paper, fabric, and metal. They have become indispensable in the realm of print styling, offering unique possibilities for customization and creativity.

In case you’re wondering what does a die cutting machine do, know that it has redefined the way we approach print styling. Through a proper die cutting process, these machines enable the production of eye-catching designs, adding depth and dimension to printed materials.

What are die cuts used for? Well, their versatility allows for a wide range of applications, from greeting cards to product packaging.

In this article, we aim to provide a comprehensive understanding of what is die cutting and what is a die cutting machine as well as what it does. We will explore their historical evolution, different types, applications in print styling, benefits, techniques, materials, what are die cuts used for, and how to choose the right one. Additionally, we will delve into the synergy between die cutting and digital printing, their role in marketing and branding and sustainability aspects, and conclude with key takeaways.

Table of Content

What Is Die Cutting: Historical Evolution

What Does a Die Cutting Machine Do: Types of Die Cutting Machines

Benefits of Using Die Cutting Machines

Choosing the Right Die Cutting Machine

Tips for Effective Die Cutting

Die Cutting and Digital Printing

What Is Die Cutting: Historical Evolution

The roots of die cutting can be traced back to ancient civilizations, where hand tools were used to cut shapes into materials. Over time, technological advancements resulted in a highly precise and efficient die cutting process

The advent of industrialization brought significant improvements to die cutting machines, making them more accessible and versatile. Modern die cutting machines now employ computerized systems for intricate designs.

The evolution of die cutting has had a profound impact on print styling, allowing for intricate and creative designs that were once unimaginable.

What Does a Die Cutting Machine Do: Types of Die Cutting Machines

Manual Die Cutting Machines

Manual die cutting machines are the entry point for beginners. They are simple to use and suitable for small-scale projects, making them a favorite among craft enthusiasts.

Digital Die Cutting Machines

Digital die cutting machines take precision to the next level. They are ideal for professionals and offer a wide range of design possibilities.

Hydraulic Die Cutting Machines

Hydraulic die cutting machines are industrial giants, capable of handling large-scale production. They are a go-to choice for businesses with high demand.

Applications in Print Styling

Greeting Cards and Invitations

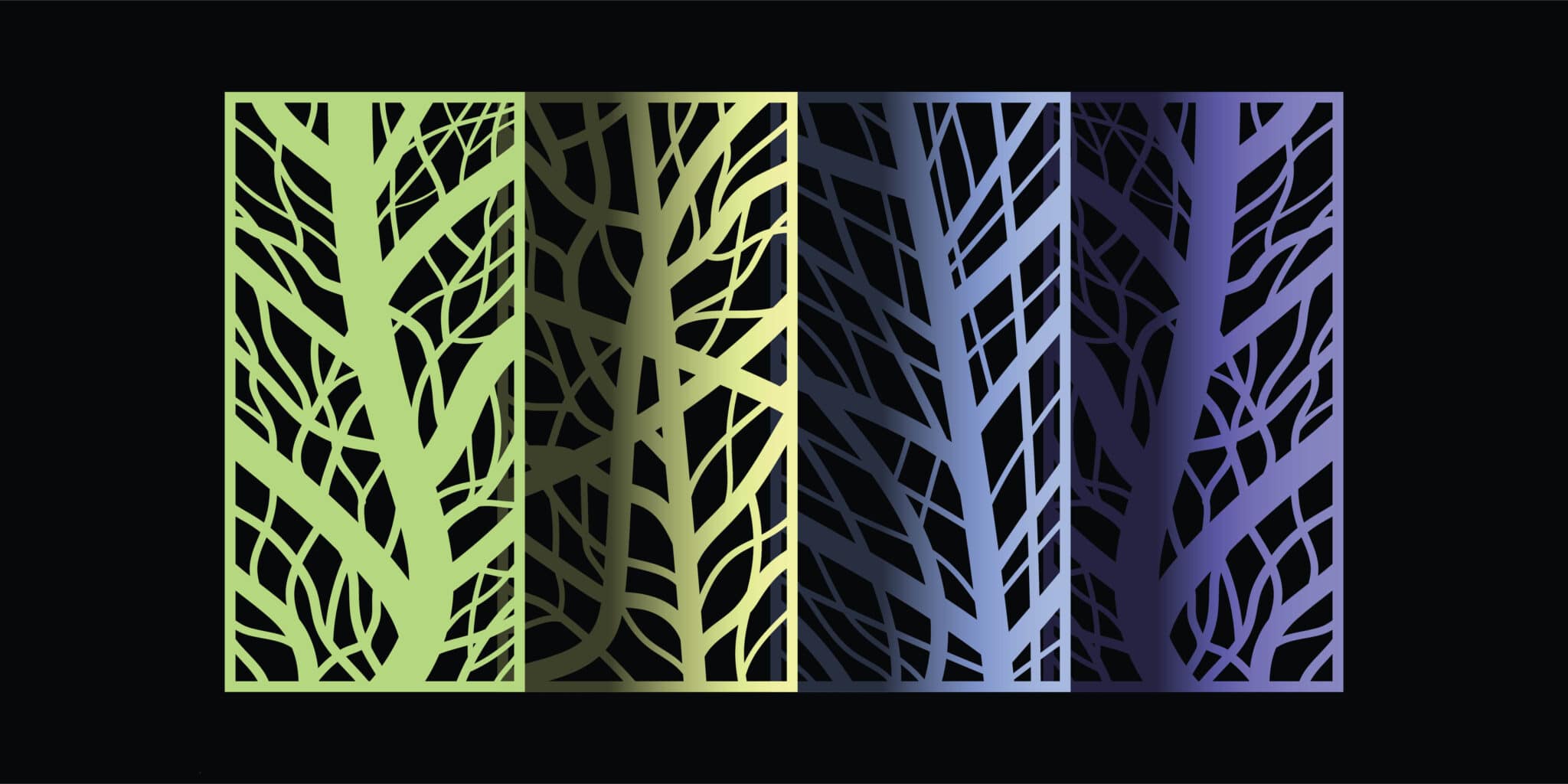

Die cutting breathes life into greeting cards and invitations, enabling intricate patterns and shapes that captivate recipients.

Packaging Design

When it comes to packaging, die cutting is a game-changer. In fact, professional die cut printing services allow for unique packaging designs that enhance brand identity.

Scrapbooking

Scrapbook enthusiasts can create stunning layouts with die cutting, adding a touch of elegance to their creations.

Apparel and Fabric Design

Fashion designers work with local custom printing services to add intricate patterns and designs to fabrics, elevating their collections.

Benefits of Using Die Cutting Machines

Precision and Consistency

Die cutting machines offer unparalleled precision, ensuring every cut is identical. This consistency is vital for professional results.

Customization and Creativity

Creativity knows no bounds with die cutting. Custom shapes and designs open up endless possibilities for unique creations.

Time and Cost Efficiency

Die cutting streamlines production processes, saving time and reducing material wastage. It’s a cost-effective choice for businesses.

Eco-Friendly Practices

Die cutting can contribute to eco-friendly practices by minimizing material waste and supporting sustainable materials.

Die Cutting Techniques

Embossing and Debossing

Embossing raises a design, while debossing depresses it, adding texture and visual appeal to printed materials.

Perforation

Perforation creates easy tear-off sections, making printed materials interactive and functional.

Foil Stamping

Foil stamping adds a touch of luxury and sophistication to print styling with metallic accents.

Kiss Cutting

Kiss cutting allows for delicate cuts through the top layer of material, ideal for stickers and decals.

Die Cutting Materials

Paper and Cardstock

Die cutting paper and cardstock is a common practice, creating intricate designs for various applications.

Vinyl and Adhesive Materials

Vinyl and adhesive materials are perfect for creating stickers, decals, and labels with die cutting.

Fabric and Leather

Fashion and upholstery industries utilize die cutting for fabric and leather applications, adding uniqueness to their products.

Wood and Metal

Die cutting isn’t limited to soft materials; it can also be used on wood and metal for industrial purposes.

Choosing the Right Die Cutting Machine

Considerations for Beginners

For newcomers, factors like ease of use and budget are crucial when selecting a die cutting machine.

Professional and Industrial Options

Professionals require machines with advanced features and capabilities, while industries rely on heavy-duty, industrial-grade equipment.

Budget and Space Constraints

Budget-friendly options and compact designs cater to those with limited resources and space.

Tips for Effective Die Cutting

Design Preparation

Effective die cutting starts with well-prepared designs that are optimized for die cutting. Make sure you get this right. Consult the professionals, if needed.

Machine Setup and Maintenance

Proper setup and maintenance are essential for consistent and error-free die cutting.

Troubleshooting Common Issues

It’s important to identify and address the common challenges users face. Offering viable solutions is key to keeping your die cutting process smooth.

Die Cutting and Digital Printing

Synergy between Technologies

Combining die cutting with digital printing enhances the overall print quality and opens up new design possibilities.

Enhancing Print Quality

Die cutting can take your print materials to the next level by adding depth and visual interest.

Automation Possibilities

Automation in die cutting and digital printing streamlines production, saving time and reducing human errors.

Die Cutting in Marketing and Branding

Impact on Product Packaging

Product packaging is a critical element of branding. Learn how die cutting can elevate your packaging design.

Brand Recognition and Differentiation

Die cutting helps brands stand out in a crowded market, making a memorable impression on customers.

Trends in Advertising

Keep abreast of the latest trends in advertising to incorporate die cutting and create eye-catching campaigns.

Sustainability in Die Cutting

Environmentally Friendly Materials

Die cutting can support sustainability by using eco-friendly materials and reducing waste.

Recycling and Waste Reduction

Efforts to minimize waste are crucial in today’s eco-conscious world. Die cutting can contribute to this cause.

Industry Trends towards Sustainability

Make it a point to learn about the industry trends that prioritize sustainability in die cutting practices.

Conclusion

In this comprehensive exploration of die cutting machines, we’ve covered their history, types, applications, benefits, techniques, materials, and tips. We’ve also discussed their synergy with digital printing, role in marketing, sustainability aspects, and future innovations.

Die cutting machines empower print stylists, designers, and businesses to push the boundaries of creativity. They play a pivotal role in shaping the aesthetics of printed materials across various industries.

As technology continues to advance, die cutting machines will undoubtedly remain at the forefront of innovation in the world of print styling. Whether you’re a beginner, a professional, or an industry leader, harnessing the potential of local business card printers and die cutting can transform your approach to print styling.