When you pick up a commercial paperback, you’re likely holding a perfect-bound book – and we don’t just mean that it’s bound correctly.

What is perfect binding? We’re referring to a popular bookbinding technique commonly used to craft catalogs, tradeshow books, workbooks, magazines, programs, and other soft-cover books.

At Digiprint’s printing services in Sparks, NV, we specialize in short-run perfect-bound books, starting from as low as 20 pages. Our in-house designers will help you design a perfect-bound book to captivate your audience from cover to cover.

In this post, we’re going to highlight the key advantages and drawbacks of perfect binding, then discuss who can benefit most from using the perfect binding method.

But first, let’s dive into how perfect-bound books are made.

The Perfect Binding Process

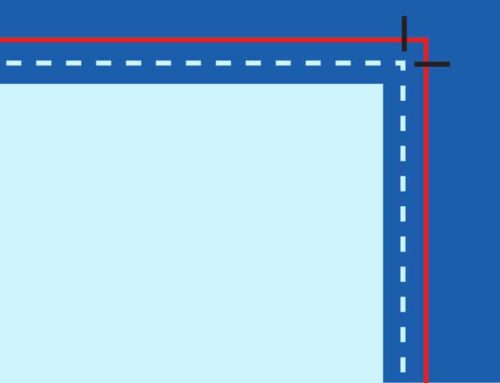

To assemble a perfect-bound book, your printer will first stack the pages into a neat, crisp block. Next, they’ll rough up the spine edges with blades or abrasives to expose more paper fibers. This increases the bonding surface area for the hot-melt adhesive.

The printer will then apply hot glue along the prepared edge and wrap the cardstock cover around the page block, making sure it sticks well to the spine. After the binding glue cures, they’ll trim the three edges to make them look ‘perfect’- which is where the term ‘perfect binding’ comes from.

For the perfect binding method to work, you need a page count between 20 to 40 to start with, depending on the paper’s thickness. This makes sure the spine is wide enough for the binding glue to work well.

Wondering how many pages you can bind between the front and back cover?

You can only compile a few hundred pages with perfect binding. Any more than that, and the adhesive might not hold perfect-bound books together as it should. Always double-check with your printer for the exact page count their perfect binding process can handle.

One key benefit of perfect binding printing services over other softcover techniques is you get a flat spine. This allows you to print titles, author’s names, volume numbers, or other identifiers on it.

Just remember: the perfect-bound book’s spine width needs to be a least a quarter-inch wide for the text to be legible on the edges.

Who Uses Perfect Binding?

Perfect binding printing is widely used across the board. It’s a great option if you want your publications to look sharp and last long – without spending a fortune.

Some of the organization types that use the perfect binding method the most include…

- Schools: Universities and colleges often use perfect-bound books to list upcoming courses with descriptions. Printed course catalogs can feature professor bios, as well as information about the campus.

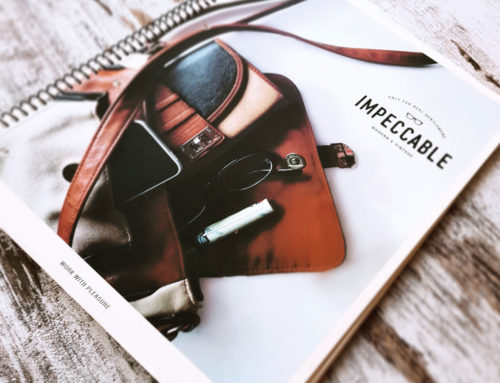

- Realtors: Realtors like to create booklets to showcase the homes they’re trying to sell. Perfect-bound magazine printing gives listings a professional appearance and lets buyers see all the options neatly compiled in paperback books.

- Clinics: Dental offices, mental health clinics, and doctor’s offices prefer perfect binding for printed service guides, educational materials, and magazines.

- Self-Published Authors: Perfect binding is a low-cost way for self-published authors to give their novels, poetry collections, or memoirs a more professional edge.

- Businesses: Businesses often choose perfect binding for printed corporate reports, catalogs, and brochures that need to look sleek and impressive. Plus, the ability to print the book’s title on the spine helps their materials get noticed and remembered.

- Event Organizers: Event organizers at trade shows can use perfect binding for their event programs and exhibition catalogs. It enables them to present detailed information in an easy-to-navigate format with a professional appearance.

Benefits of the Perfect Binding Method

Perfect binding is a fantastic option for publishing and printing projects for many reasons, including its affordable price. Some other benefits of perfect binding include:

- A clean, polished look that shows off your work’s quality.

- Printed titles and names on the spine, highlighting your work on a bookshelf.

- Smaller print runs – a budget-friendly way to create high-quality bound books.

- Strong glue that keeps the book pages in place and protects the document.

Perfect binding can also accommodate a variety of paper weights, colors, and finishes. The process is incredibly versatile and fit for a wide range of printing jobs and production times.

Limitations of Perfect Binding

Like any method, perfect binding comes with its own set of downsides.

- Perfect-bound books cannot lay flat when open. Hence, they are not ideal for things like cookbooks or instruction manuals that need to offer hands-free reading experiences. For those, you’ll need to look into flat binding techniques.

- There’s a limit on the number of pages that can go in perfect-bound books. Very thick or thin publications might not be suitable for this binding method.

- While durable, the perfect binding method may wear out with intense, repeated use, especially with very thick volumes.

Consider these drawbacks to see if perfect binding is the best choice for your project. You can also ask the binding experts at Digiprint. We’ll be happy to recommend perfect binding or another common technique, such as saddle stitch binding.

Digiprint | Perfect Binding Work You Can Trust

There are many reasons to invest in a quality-printed, perfect-bound book. If you have any additional questions about this low-cost binding technique, feel free to reach out to the team at Digiprint. We’re proud to be Reno’s go-to choice for superior printing and binding options.

Call us to see what our team and perfect binding machine can do for you.